Deck Inspections Needed For Your Deck Construction

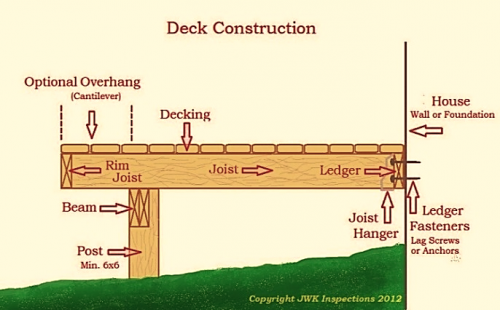

According to estimated reports by the National Association of Certified Home Inspectors (InterNACHI) over 2 million decks are built and/or replaced each year in North America. Along with that InterNACHI, the worlds largest and most recognized Home Inspectors Organization estimates that of the 45 million or more existing decks, that no more than 40% are completely safe. This would obviously be due to improper and inadequate construction techniques. Here, we will look at Deck Construction techniques along with Deck Safety including what applies to our local San Antonio areas. Image shows deck construction with the optional cantilever (overhang). The overhang area should not be more than 1/4 the span of the entire length of joists. Decks may appear to some people, to be fairly easy or even simple to build themselves, but you should not try it yourself, unless you are well qualified in the trade and up on the requirements that make it a safe structure. If you're not, hire a professional that is a specialist in deck construction. Many people do not realize that decks are, in fact, structures that need to be designed to adequately resist certain loads, resistance and stresses. This is especially true to decks as they get higher off of the ground level. Like buildings and homes or even other structures a deck must be designed to support the weight of people, snow loads (in northern areas), along with the weight of many other different possible objects on the deck area along with wind resistance, etc. A deck must be able to resist lateral and uplift loads. The more proper footings and posts there are your deck has to distribute the total load, the less weight each footing will need to carry. Deck footings along with the posts that are properly attached to or imbedded in the concrete footings spread the heavy load of the deck from the surface along with the frame over a larger area of the grade so the ground can adequately support it. Joists should run perpendicular to the house. Beams must sit on top of posts, not be fastened to the side of posts. Beams that butt into another beam should be supported by a hanger. Joists can sit on top of the beam or if it butts into it joist hangers are used to attach the ends of joists to the face of a beam or to the ledger board. The Decking- The Guard Rail System- Deck Failure: Deck failure is any failure of a deck that could lead to injury, including railing system failure along with the total or partial collapse of a deck from improper ledger attachment to the home or improper structural frame including installation or sizing of joists, beams and posts. Supposedly, there is no international system that tracks deck failures, and usually each is treated as an isolated, independant situation, rather than a systemic problem. Overall, very few municipalities, jurisdictions perform investigations into the cause of deck failures, and the media is usually more concerned with the injuries of deck injuries rather than on the causes of injuries. Here are some facts about deck failure: •More decks collapse in the summer than during the rest of the year combined. •Almost every deck collapse occurred while the decks were occupied (usually with more than just the minimal occupants). •There is no correlation between deck failure and whether the deck was built with or without a building permit. That's because the deck can be built properly built with or without a permit. •There is no correlation between deck failure and whether the deck was built by a homeowner or a professional contractor. That's because a deck can be built properly with or without a contractor. The important thing is to build a deck properly following all reommendations, codes and proper industry standards. •There is a slight correlation between deck failure and the age of the deck. •About 90% of deck collapses occurred as a result of the separation of the house and the deck ledger board, allowing the deck to swing away from the house. It is very rare for deck floor joists to break mid-span. •Many more injuries are the result of rail failure, rather than complete deck collapse. •Deck stairs are notorious for lacking graspable handrails. •Many do-it-yourself homeowners, and even contractors, don't believe that rail infill spacing codes apply to decks. Recently there are more and more investigations by local jurisdictions of deck failures due to the recent excessive deck failures reported in the media. Awareness helps improve safety Information and Inspection Images by Joseph W. Keresztury, JWK Inspections Contributing info and/or other images by: InterNational Association of Certified Home Inspectors (InterNACHI), International Residential Code (IRC), Prescriptive Residential Wood Deck Construction Guide (American Wood Council and American Forest and Paper Association, Decks.com '

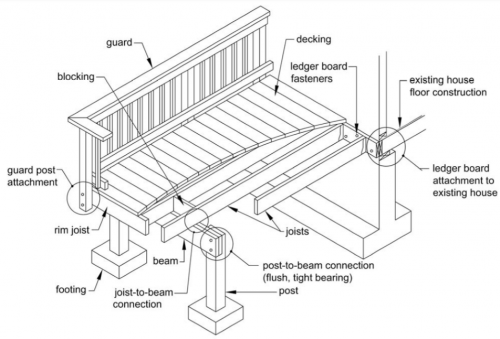

Components of a Deck:

The Footings and Posts-

Footings are very important components of deck construction because they provide the solid foundation that will support your deck. The posts (columns) will sit on the concrete footing with proper fastening or in most cases in the encased concrete footing below the ground level. The posts should be a minimum 6x6" and be of a treated lumber material.  Photo at a Seguin, Texas Home and Deck Inspection shows Improper concrete footing for the post (column) verified here, as seen with screw driver imbedded in ground around post along with the gap between post and minimal concrete.

Photo at a Seguin, Texas Home and Deck Inspection shows Improper concrete footing for the post (column) verified here, as seen with screw driver imbedded in ground around post along with the gap between post and minimal concrete.

The Ledger-

Attaching the deck ledger board properly to the house on a non-freestanding deck is of the upmost importance. The 2x ledger board needs to be equal to or greater than the size of the joists being used.  Photo here is of a of a Helotes,Texas Home Inspection- A bolt fastener at ledger board to slab foundation is shown. There are however an inadequate amount of fasteners as needed as per requirements at the area shown.

Photo here is of a of a Helotes,Texas Home Inspection- A bolt fastener at ledger board to slab foundation is shown. There are however an inadequate amount of fasteners as needed as per requirements at the area shown.

Fasteners (bolts or lag screws) depending on whether it is a connection to the foundation or to the solid exterior wall should be installed, in many cases around every 12 to 16" OC (depending on sizing) alternating top and bottom third thru ledger into the rim board (rim joist) of house or into the foundation. Ledgers should not be fastened into/thru masonry veneers (brick, stone) or into/thru overhanging boxed out areas of house frame such as bay windows, etc.

The Framing-

Beams and Joists of the deck are the structural members that are what is used to build a deck frame and are installed after posts with proper footings and the ledgers are installed. Beams and joists maintain the shape, strength and integrity of a deck. If these members are not properly sized or installed issues may occur to cause problems that may not occur for years to come, but will eventually occur.

This San Antonio area home inspection photo (left) shows the deck frame joists butting into a perimeter beam without joist hangers installed. Joist hangers or a ledger (or ledger strip) are acceptable in this case to secure joists to the beam. Photo at right shows a sample of proper attachments with a joist hanger. A ledger strip if used should not be more than 1/3 of the joist size. Overcuts on the joist notches to install on a ledger strip shoud be avoided. Some jurisdictions may allow pressure blocks as an alternate support for joists attaching to a beam or ledger board in lieu of joist hanger or ledger strip.

Joists are installed parallel to each other for ease of construction and to distribute weight evenly for structural integrity. Even spacing of course down along joists is important since lumber for the decking material comes in 2 foot increments which works out with well with common joist spacings of 12, 16 or 24" on Center (OC).

For many years decking was primarily wood. People used redwood, cedar, pressure treated pine, and even some exotic woods. Wood has some beautiful natural charecteristics but also requires some maintenance. Decking comes in many forms these days. There are many type man made decking products on the market today. Most are composed of a composite or vinyl material. Decking is usually nailed or screwed to the joists for the attachment. A nail or screw should be used as a spacer between decking boards. Over spacing between board placement could cause safety issues.

The Stairs-

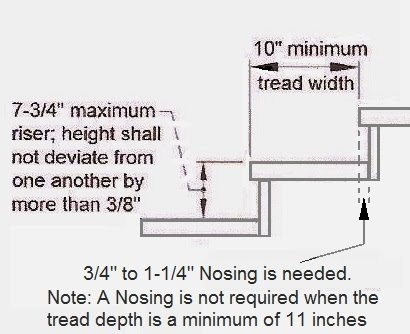

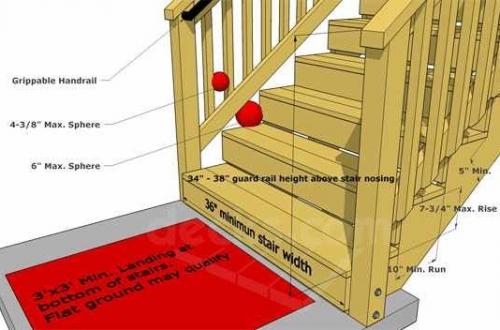

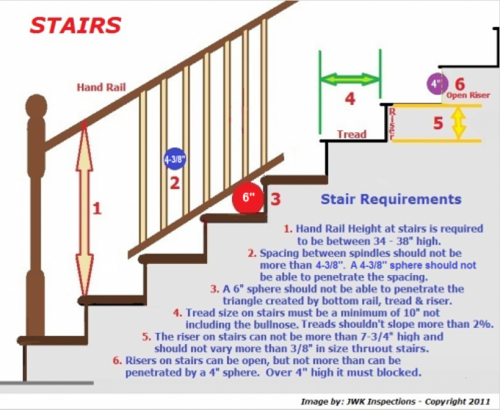

When stairs for your deck are built, they should be in accordance with the (International Residential Code (IRC) building requirements. The minimum allowable width for stairs is 36". The maximum riser height of steps should be 7-3/4" and the minimum recommended riser is 4". If risers are more than 4" high they should not be left open. The minimum stair tread depth should be no less than 10" not counting the bullnose. So basically your treads should be a minimum 11". If their is no bullnose than the tread should be at least 11".  Tread width sizes and riser heights should not vary more than 3/8" from each other.

Tread width sizes and riser heights should not vary more than 3/8" from each other.  Image (Decks.com) shows deck stair requirements.

Image (Decks.com) shows deck stair requirements.

Deck stairs and rails must be safe and handrails graspable. And, finally, deck rails should be safe for children by having proper infill spacing. Photo shows improper stair fastening to the deck at this Cibolo, Texas area Home Inspection.

Photo shows improper stair fastening to the deck at this Cibolo, Texas area Home Inspection.

Additional Stair & Rail Info:

http://www.jwkhomeinspections.com/Blog-Stair-Safety-Requirements-Standards-Hand-Rails-San+Antonio-Home-Inspections.html

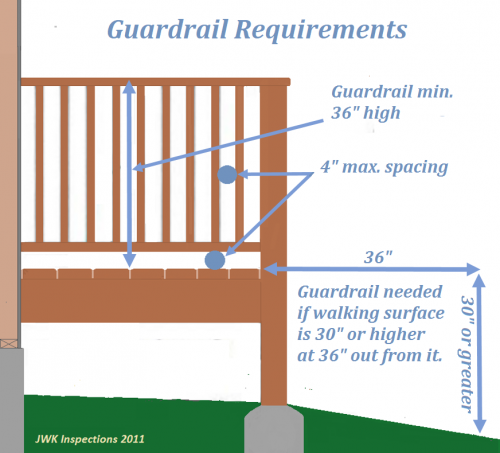

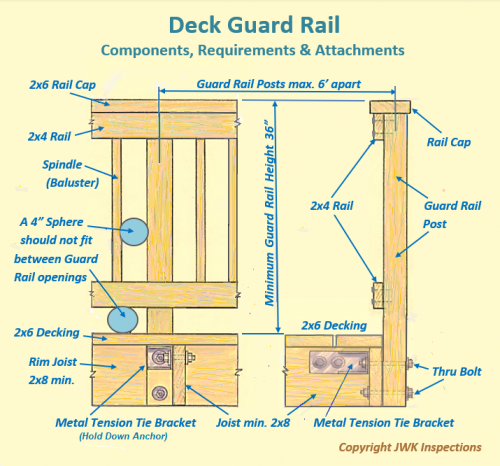

Over recent years the deck industry has developed a variety of attractive rail systems. Because your deck's rails will be one of the most visible features of your new deck, it is important to choose a rail that complements your decking material and the style and color scheme of your house. Guard rails are required any time your deck surface is 30" or higher above grade, including within 36" of the walking surface. Spindle spacing should not be wider than 4" apart and the bottom rail should not have more than a 4" clearance from the decking.

Over recent years the deck industry has developed a variety of attractive rail systems. Because your deck's rails will be one of the most visible features of your new deck, it is important to choose a rail that complements your decking material and the style and color scheme of your house. Guard rails are required any time your deck surface is 30" or higher above grade, including within 36" of the walking surface. Spindle spacing should not be wider than 4" apart and the bottom rail should not have more than a 4" clearance from the decking.

Rail failure occurs much more frequently than deck collapses. However, because rail failures are less dramatic than the issues of partial and even entire collapses of a deck and normally doesn't result in death, injuries from rail failures are rarely reported.

San Antonio Home Inspector, Commercial Inspector, 'Owner Builder' Consultant and New Home Construction Specialist

Post new comment